DESCRIPTION

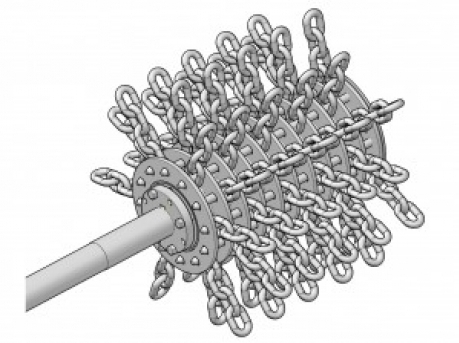

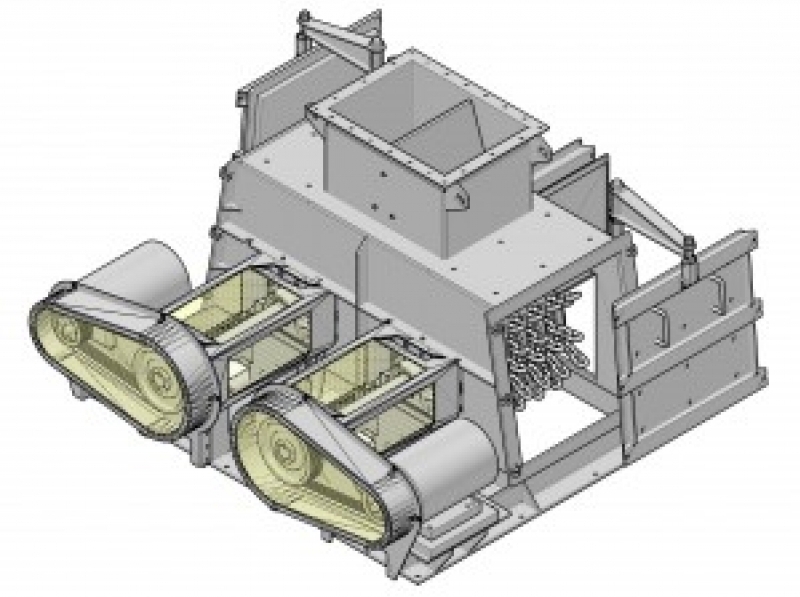

Chain mills are machinery designed to reduce the particle size of a material by impacting between the material with a series of high-speed current links. In a double rotor current mill, there are two independent current rotors rotating in opposite directions. The direction and speed of rotation of the rotors, the spacing between rotors, and carefully managed material flow path through the machinery contribute to the high efficiency of the HD MOD III J&H chain mill. Solid construction, wear-resistant material plates and liners, and a unique vibration isolation system provide exceptional durability and long mill life. Large doors on the machinery provide full access to the rotors for inspection and maintenance. Various sizes of chain are available to meet your application needs.

Current mill efficiency comes not only from the correct rotor speed, but also from the setting of the currents. J&H has standard rotor designs for each mill size. Proper spacing between the chains allows a portion of the material to fall below the path of the chains before they are impacted. The double rotor configuration also provides multiple impacts of material as it passes through the mill. The number and configuration of currents in each rotor was determined by J&H in order to maintain rotor balance and extend the life of the currents by distributing the impact over a large area of the current. This results in increased efficiency while reducing maintenance.

A unique and innovative feature of the HD MOD III J&H chain mill is that the rotors are completely supported and moved on one side of the machinery. This configuration allows for wide access doors at the front and sides of the machinery providing easy access to all the points that need to be reached to perform services. It positions all mechanical parts of the machine on one side for easy inspection and maintenance and evaluation of mechanical systems. In general, maintenance of mechanical systems is easier and more efficient.

The inner bearings, which support most of the rotors weight, are mounted on rubber tracks, allowing the shafts to respond individually to starting and stopping forces as well as the various impacts that occur during machinery operation. The flexion of the rubber tracks against the rigidity of the frame support absorbs the rotor movement and dissipates the stress generated in the shaft. This takes loads off the bearings, extending their life. Vibratory forces common in most current mills are dissipated and reduced to negligible amounts in the mill frame. The advantage is that the HD MOD III J&H chain mill does not need to be isolated from the plant structure and can be mounted directly on the concrete floor using standard screws.

Webmail

Webmail