DESCRIPTION

Fabric fabrication is not perfect, often with slight variations in width. Wires that are not tensioned uniformly will have variable vibration amplitude, creating vibration knots and dead zones. Even worse, without an optimizer system, it's easy to apply non-uniform tension that can pull the screen thread off center or inadvertently stretch parts of the screen while leaving other parts slack. When this happens, it is not possible to easily fix it. Changing the tension afterwards will only leave a flabby part of the screen. Wires that are not tensioned will quickly deteriorate due to fatigue failure caused by high frequency vibrations.

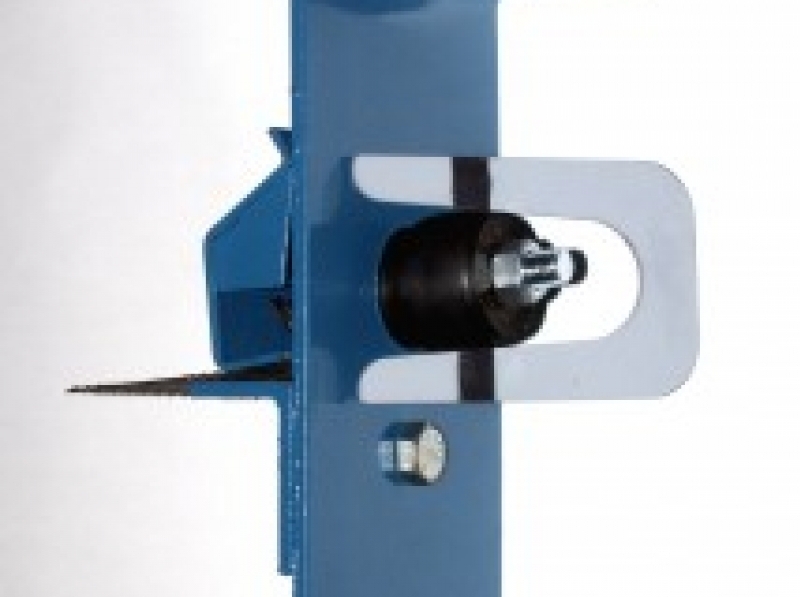

When a screen is installed on a J&H machine, a set of five rubber pads on each side of the screen applies tension to the wires. These act like springs, but rubber will not corrode and unlike metal, its spring constant is temperature independent, rapidly losing force as temperature increases. The rubber used in cushions is waterproof, heated up to 150 °C.

The most innovative feature of the pad is the ability to directly measure the amount of tension applied to the wires. The image illustrates an example of J&H's unique strain gauge (metal gray U-shaped tool). As shown, a specific voltage value can be determined using this meter. Used correctly, this allows the tension in the wires to be evenly optimized for all ten pads alongside the screens. When all ten pads are at the same voltage value, the laws of physics and energy conservation dictate that the voltage in the wires must also be at the same value everywhere, regardless of small imperfections in the mesh, or when changing a screen. old by a new one.

Screens of different meshes, wire diameter or wire material can be given individual tension values to ensure that not only an individual screen is tensioned correctly, but different types of screen on the same machine (such as the upper and lower deck of a double deck screen ) are vibrating together as one. When the tension in the threads is optimized, your screen will function like a well-tuned sports car, the screening efficiency increases, the energy usage for the vibration motors decreases and the life of the entire machine is extended.

Webmail

Webmail