DESCRIPTION

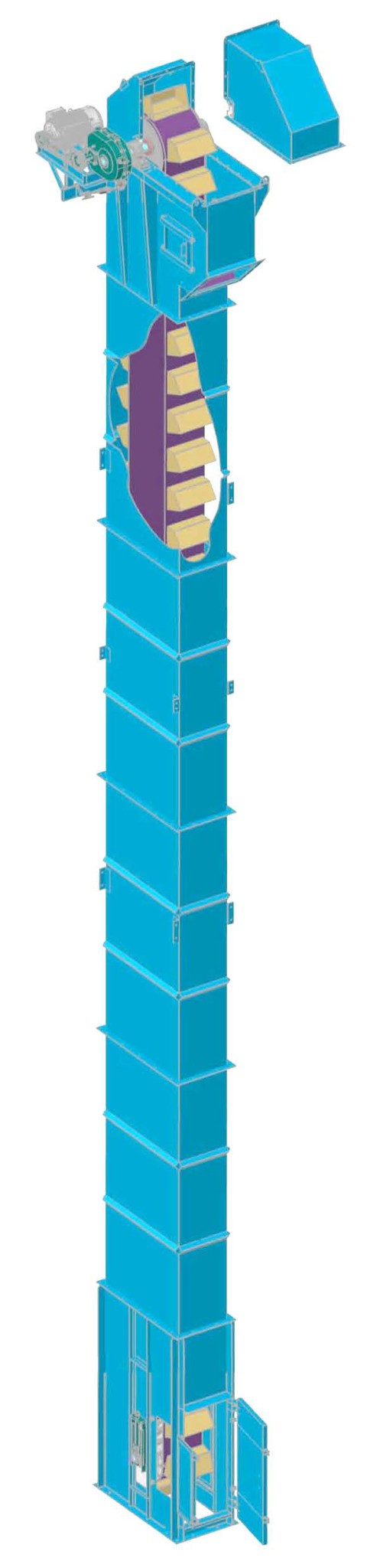

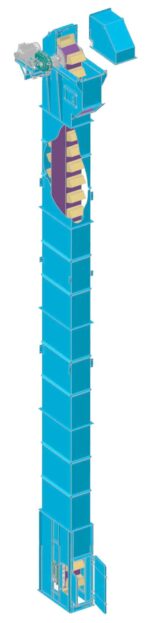

The Belt Mug Elevator is a heavy duty mug elevator. The elevator mugs are screwed onto the conveyor belt. This has an advantage over double chain elevator design in lower capacity elevators. The belt is easier to install, inspect and maintain. The elasticity and flexibility of the belt material provides adjustments for small misalignments of the elevator structure. When designed using a conveyor belt, rubberized pulleys and wing-type pulleys are used. Drum pulley and power screw provide smooth operation with good traction. A wing type pulley is used at the base to prevent abrasive material behind the belt from causing wear.

Belt elevators can be centrifugal or continuous discharge. Centrifugal elevators can be operated at higher speeds. They are called such because of the centrifugal forces generated by the buckets at the top, which help unload material from the buckets, throwing the material into the discharge chutes. Continuous operation is slower, with the mugs installed side-by-side. This allows the material being discharged to slide onto the angled plate of the lower mug. This gentler discharge method prevents breakage of more fragile materials and reduces dust generation. Each type is available with capacities ranging from 30 to 270 tph. The mugs are available from 10″ to 18″ in width and in varying thickness and type of steel depending on manufacture.

Webmail

Webmail