DESCRIPTION

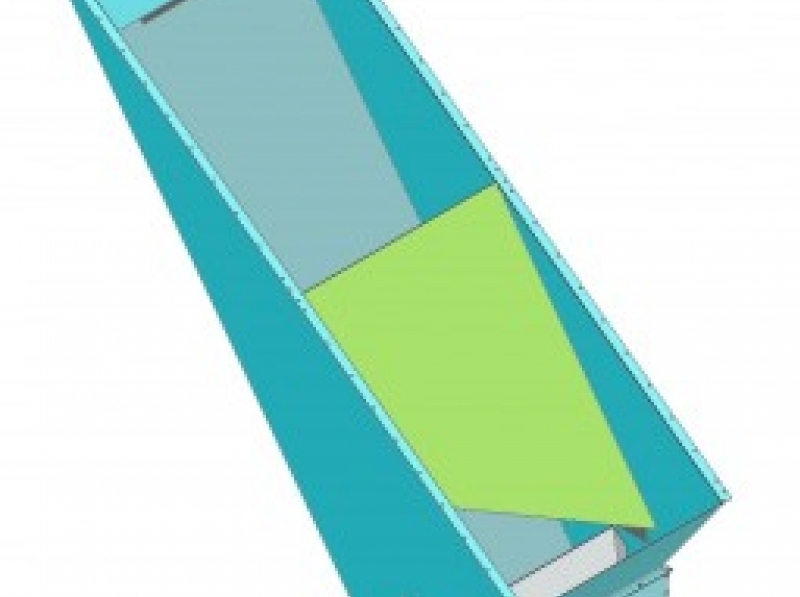

Inside the Funnel with Discharge Modulator Valve there is an angle separator that guarantees the removal of material in the modulator gate below the funnel. The purpose of this integrated sieve system is to separate material smaller than 3 mm and send it back to the granulator, with a constant and controlled flow. When the production process stabilizes, the effect of this gate is to eliminate or minimize product scrap in the recycling cycle, preventing the creation of large particulates and stabilizing the recycling flow.

Directly attached to any J&H sieve, this funnel is as wide as the sieve and allows for wide divider blades. Width is an advantage as the gate can reject the correct amount of recyclable/fine material. It also allows flow from the entire top screen to be transmitted to the bottom when arranged in series, eliminating long chutes and feeders, aiding in places where space is a concern. Wide access points allow for easy cleaning and maintenance of internal components. The stainless steel divider blade is driven by electromechanical, linear or rotary actuators, or pneumatic actuators controlled by 4 to 20 mA signals. As an option, independent IP65 limit switches combined with a local control panel or DCS control system provide flexibility for the operator, thus helping to stabilize the chemical process and improve final product quality.

Webmail

Webmail