DESCRIPTION

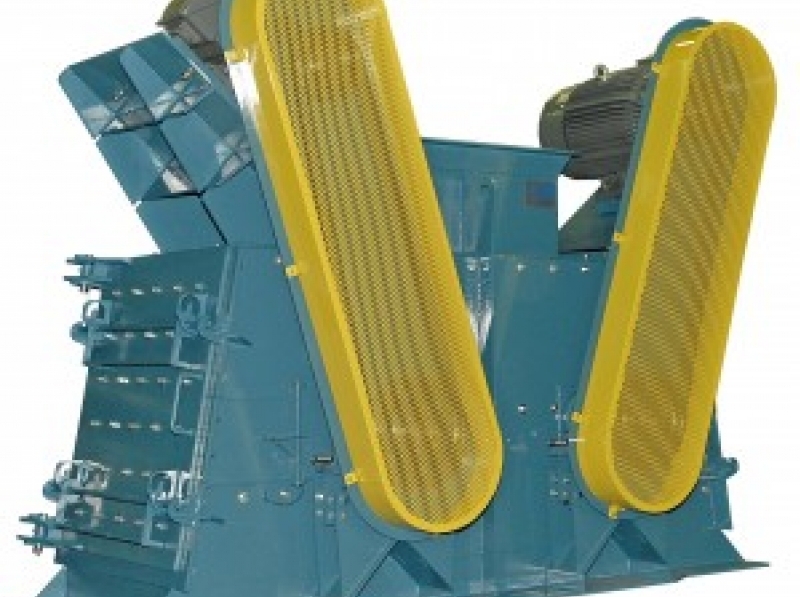

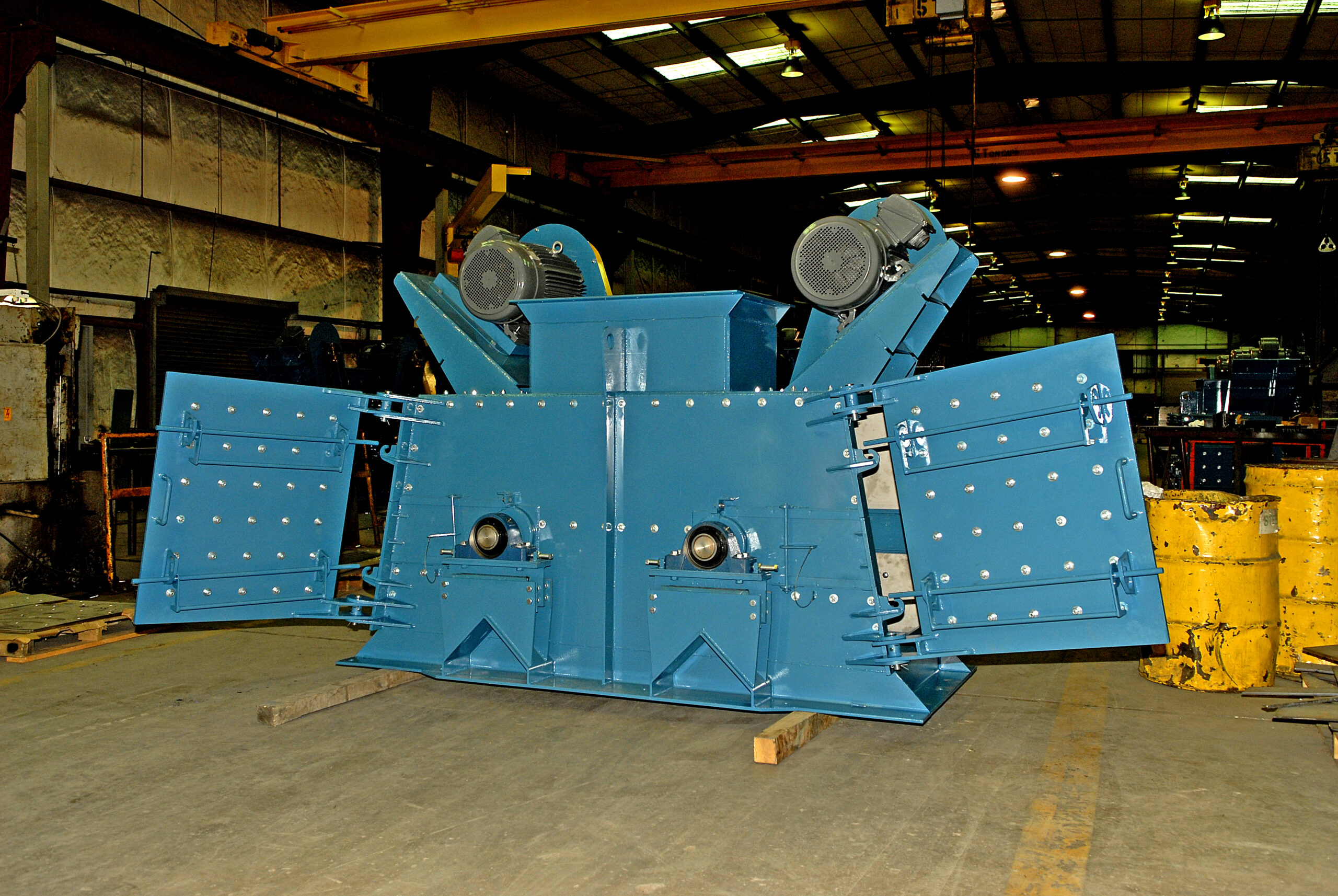

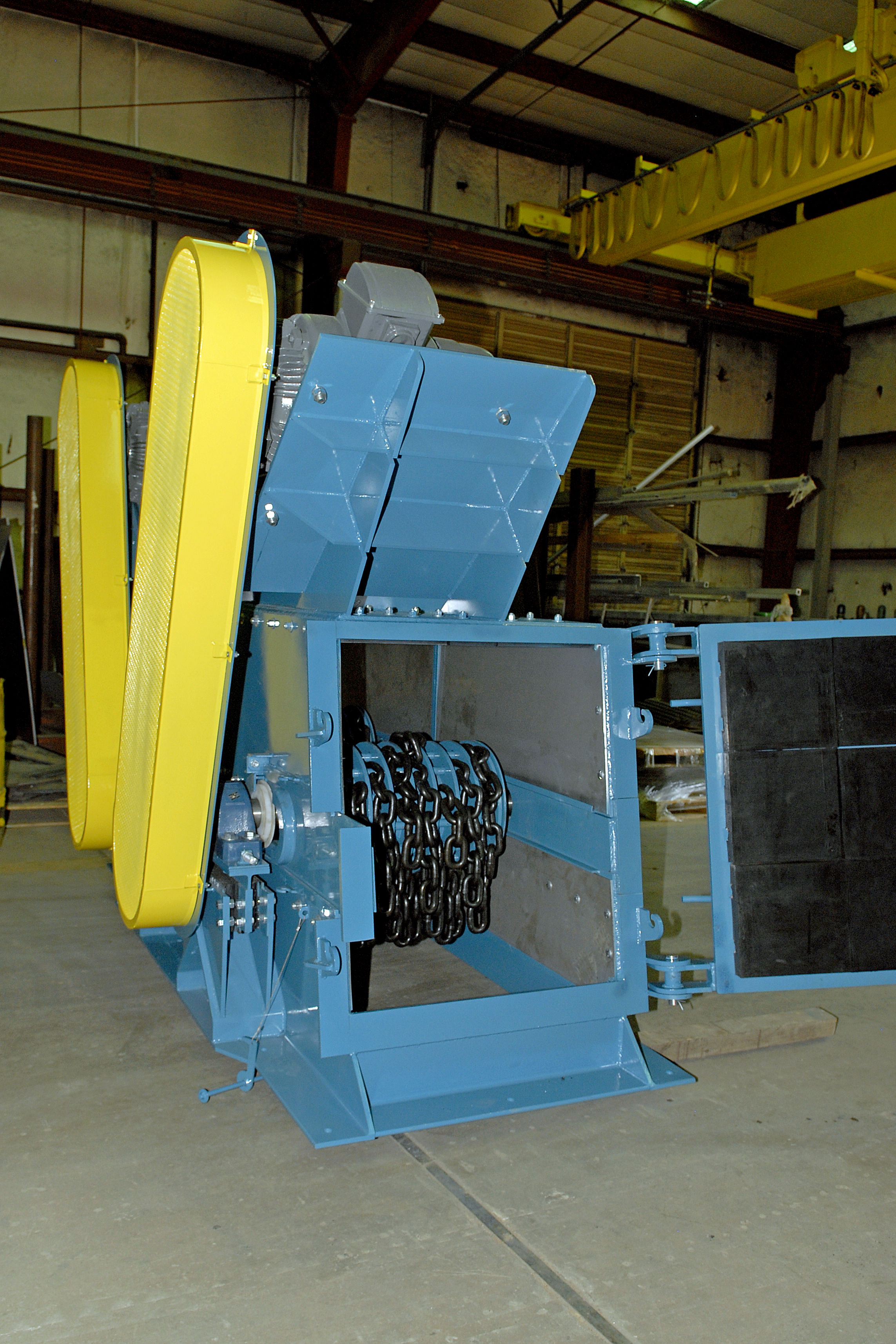

Compared to the standard chain mill, the HDS and HDF models have a smaller footprint and compact configuration, which is essential in applications where space is limited. However, in the design of the HDS and HDF models, all the consecrated design features of the HD version were kept. The balanced rotors are the same. Usual maintenance can be performed on the side doors, which open fully, providing full access to the rotors and all parts of the mill interior. Chains can be inspected and exchanged without having to dismantle any other part of the mill. The side doors are heavy enough to provide the necessary protection from impacts that occur during operation, yet they are balanced on a suspended arm so that only one person is able to handle them. Impact surfaces are lined throughout with abrasion resistant rubber.

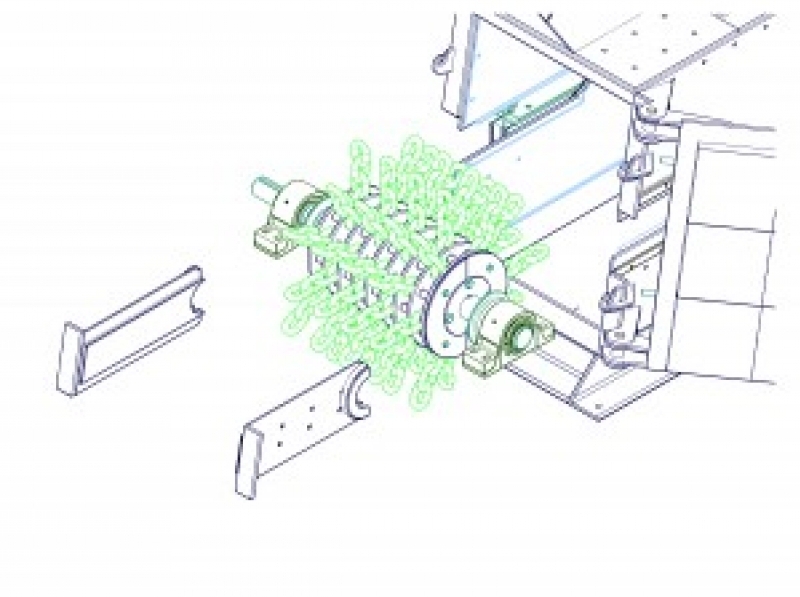

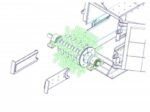

However, when more extensive maintenance is required, for example when bearings or liners need repair, it is necessary to remove the entire rotor from the machine assembly. It is necessary to dismantle two small sliding plates, unscrew the bearings and remove the rotor from the mill casing. Working with these parts in a controlled and unobstructed environment allows for better and faster work.

In the HDS version, bearings are coupled on each side of the frame so that the rotor shafts can respond to starting, stopping and impacts when the machine is in operation individually. This reduces the forces generated on the shafts, which reduces stresses on the bearings and the forces transmitted to the frame. The HDS MOD III J&H chain mill does not need to be insulated from the plant structure and can be mounted directly on a concrete floor with standard screws.

Webmail

Webmail